- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: LUEN groups Publish Time: 2024-08-05 Origin: Site

which leaf spring to remove to soften ride:

To significantly improve ride comfort, it is recommended to consider removing the trailer's third leaf spring. This operation usually causes the spring system to sink approximately 1 to 2 inches, although the exact amount will vary depending on the actual condition of the trailer leaf spring. Such adjustments can significantly enhance ride comfort. Thankfully, if you try it and find it doesn't work as expected, you can always easily put the removed leaf trailer spring back into place.

How to choose the right leaf spring:

When choosing the right leaf trailer springs for your vehicle, the first thing to consider is the vehicle's load-carrying capacity. Different types of leaf springs are designed for vehicles with different load-carrying needs, so it's important to make sure the springs you choose match your vehicle's load-carrying capabilities.

Which part of the vehicle is equipped with leaf springs?

Leaf springs play a vital role in the suspension systems of trucks, jeeps, vans and SUVs. These long and slightly arched spring combinations are generally placed at the rear end of the vehicle as a replacement for coil springs and link arms.

They cleverly position the rear axle directly under the chassis to ensure the vehicle's center balance in the left-right and front-to-back directions; at the same time, they are also responsible for carrying the entire weight of the vehicle itself and its cargo. In addition, these truck leaf spring combinations also give the rear suspension the necessary mobility. Through compression and extension, the rear axle can rotate flexibly, thereby achieving smooth and reliable driving.

What is the service life of leaf springs?

On the premise of avoiding road salt erosion and overloading, the service life of the truck leaf spring is almost equal to the overall life of your vehicle. However, if it is frequently exposed to harsh usage conditions or driven on salty roads, its service life may be significantly shortened.

On the other hand, if the vehicle is properly maintained, rubber bushings can usually last 10 to 15 years. But if it suffers from abuse or neglect, this number will be greatly reduced.

Is it safe to continue driving after a leaf spring breaks?

While technically possible, continuing to drive after a broken leaf spring is strongly not recommended.

Leaf springs are core components of vehicle suspension systems. Once their integrity is compromised, continuing to drive will greatly threaten the safety of you, your passengers and other road users. Therefore, once you find obvious damage to the leaf spring, or suspect that it has been damaged based on abnormal vehicle handling, please park the vehicle safely on the side of the road immediately until the problem is properly resolved.

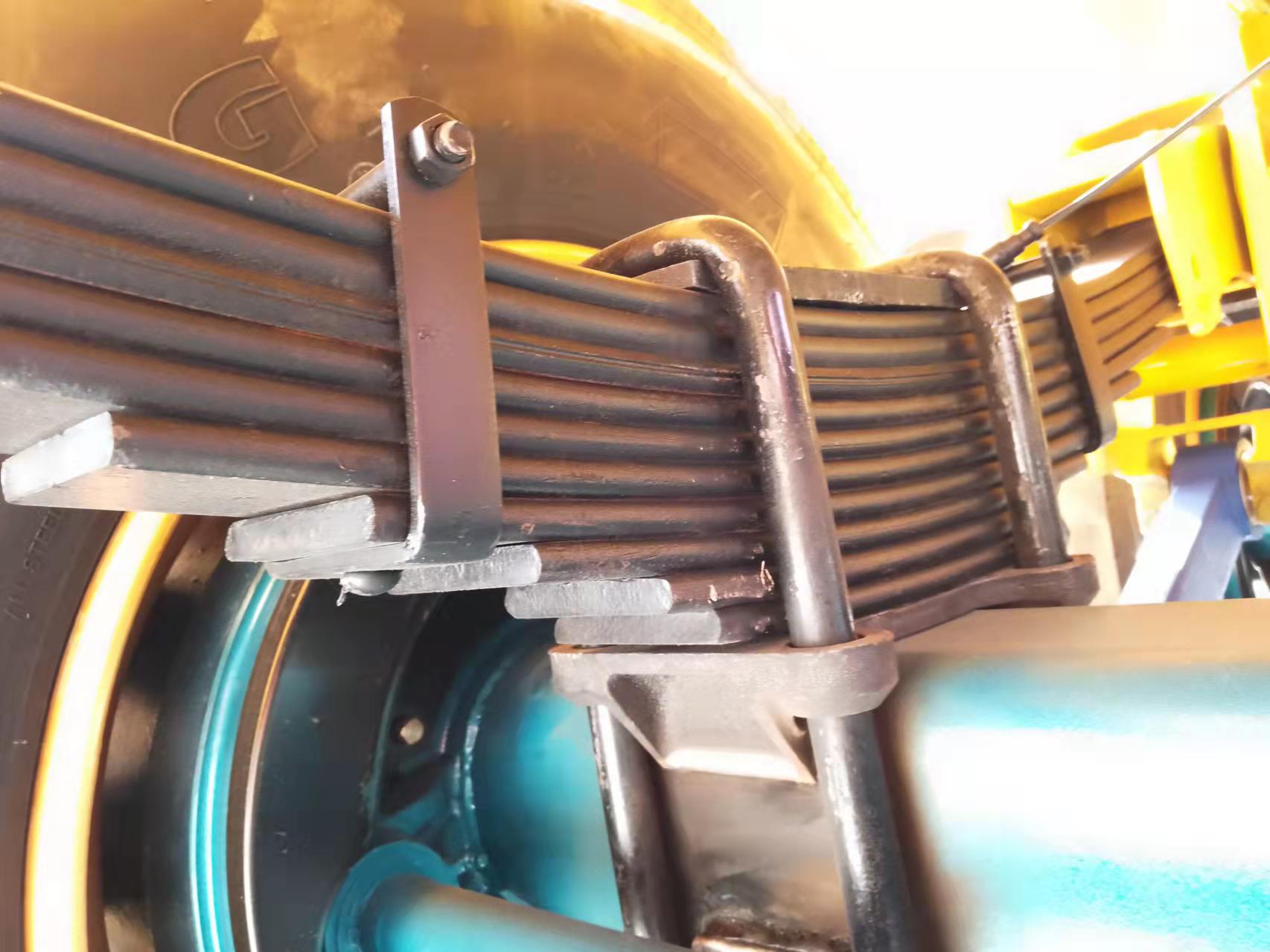

Can leaf spring U-bolts be reused?

LUEN strongly recommends not to reuse leaf spring U-bolts. It is not that we want to sell you products, but it is very unsafe.The following are the reasons why reuse is not recommended:

The main reason:

Leaf spring u-bolts are essentially torque-yielding fasteners whose characteristic is that once tightened to a specified torque standard, they will stretch to achieve the required tightening state. However, there is a limit to this stretch, and with each additional tightening operation, the truck leaf springU-bolt is closer to its critical point of failure. This poses a risk that cannot be ignored and is not worth trying.

Secondary factors:

There is a significant difference in tightening performance between old and new U-bolts, which is mainly attributed to the wear mechanism of the threads. During the repeated tightening process, the threads will not only deform under the action of torque, but will also be gradually cut and worn due to the tightening of the nut, forming grooves. This physical damage creates hidden dangers for the U-bolts to loosen. Coupled with the accumulation of corrosion, dirt, oil stains and daily wear, even if the standard torque value is reached, the clamping force will be greatly reduced, making it difficult to ensure that the blade set is stable.

Another key reason:

The original U-bolts are often not long enough to handle the installation needs of aftermarket truck leaf springs. In actual operation, we frequently encounter situations where the axle is loosened and even the suspension is damaged due to mismatched bolt sizes. The reason is that aftermarket or upgraded leaf spring sets are generally thicker and contain more levels of blades within the internal structure to accommodate higher load carrying capacity and/or vehicle elevation requirements. Therefore, the length of the original U-bolts is limited and cannot be effectively fixed and fully tightened on these leaf spring groups.

As a Chinese leaf spring manufacturer, LUEN has always been our mission to provide cost-effective products. We not only provide customers with satisfactory products, we also provide after-sales guarantee for our products.

content is empty!