Views: 0 Author: LUEN Group Publish Time: 2024-12-09 Origin: Site

Leaf spring clamps are vital components that ensure the stability and performance of leaf spring suspension systems in vehicles. As a manufacturer of high-quality trailer parts, LUEN takes pride in providing reliable solutions for all suspension needs. In this article, we will explore the details of leaf spring clamps, their structure, functions, maintenance, and common issues, offering a comprehensive understanding of their role in suspension systems.

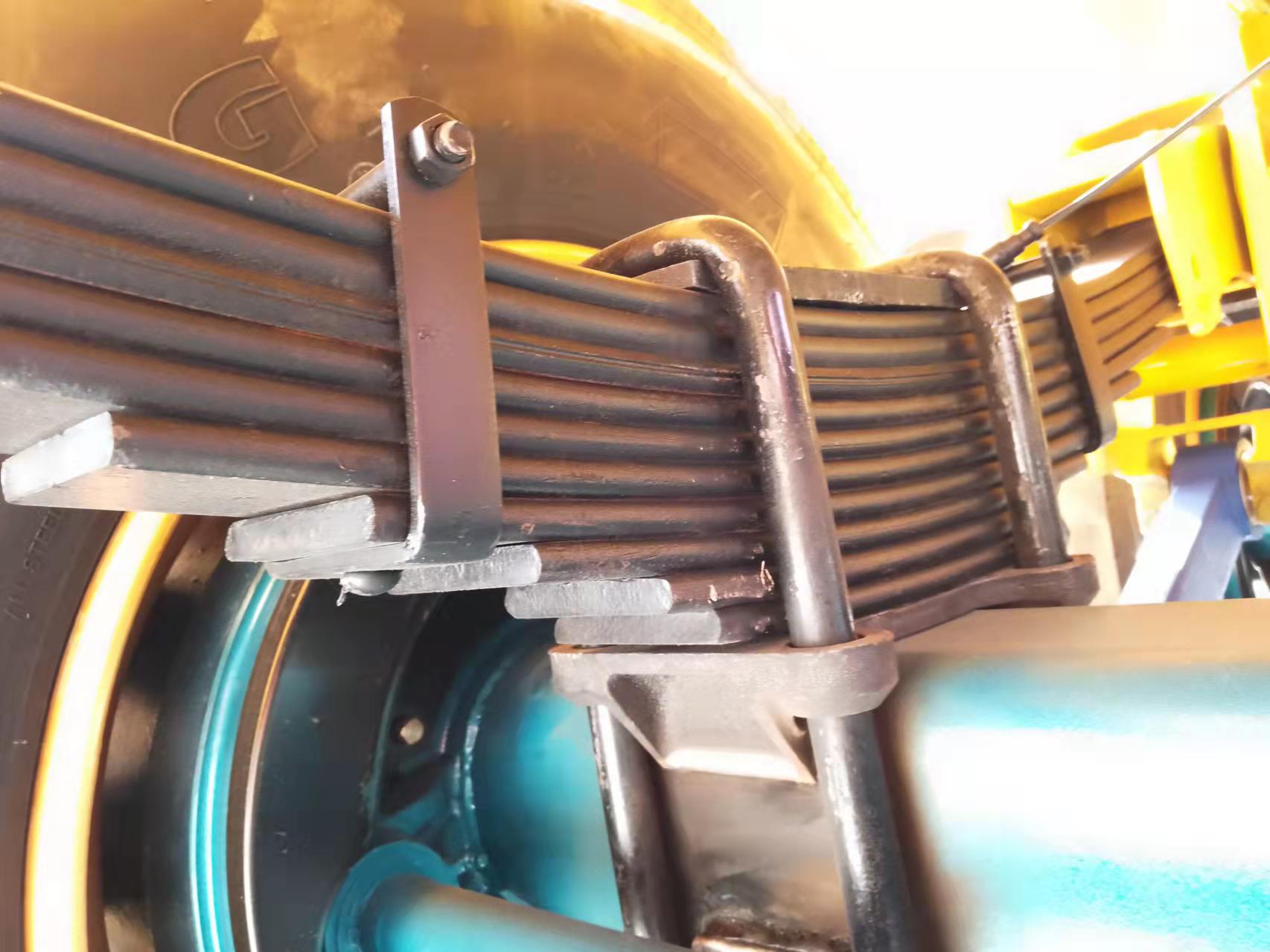

Leaf springs are a key component of vehicle suspension systems. They consist of a series of steel plates (also called "leaves") stacked together, typically in a tapered shape, and are designed to absorb shock and maintain the vehicle's ride height under varying load conditions. Leaf springs are commonly used in both light-duty and heavy-duty vehicles, including trucks, trailers, and buses.

The primary function of leaf springs is to support the vehicle's weight and absorb shocks from the road. By flexing and compressing under load, they provide a smooth ride and maintain vehicle stability. Leaf springs are especially popular in heavy-duty vehicles because of their durability, strength, and ability to handle large amounts of weight. However, to function effectively, leaf springs need to be properly secured and aligned—this is where leaf spring clamps come in.

A typical leaf spring consists of several parts, including:

Main Leaf: The largest and strongest leaf, providing the primary support.

Helper or Auxiliary Leaves: Smaller leaves that assist the main leaf in distributing the load and providing additional strength.

Clamps: These are the fasteners that hold the individual leaves together, ensuring that the spring pack remains intact during compression and expansion.

Leaf spring clamps play a crucial role in maintaining the integrity of the leaf spring pack. By securing the individual leaves together, the clamps ensure that the spring operates as a unified system. Without these clamps, the leaves could shift or separate under load, which could lead to failure or compromised performance.

Leaf springs and their clamps are typically made from high-strength steel, such as spring steel, which is designed to withstand the high stresses of compression and bending. This material ensures long-lasting durability and resilience, essential for heavy-duty applications. In some cases, leaf spring pack clamps may be made from other alloys or materials with enhanced corrosion resistance, depending on the specific needs of the application.

One of the primary functions of leaf spring clamps is to maintain the proper position of the leaf spring pack. The clamp ensures that all the leaves stay aligned and that the load is distributed evenly across the entire spring pack. This positioning is vital for the suspension system’s efficiency and for ensuring the vehicle remains stable during driving.

Leaf spring clamps also help in stabilizing the axle of the vehicle. By keeping the leaf spring pack in place, they prevent unnecessary shifting of the axle and ensure that the suspension system functions optimally. This is particularly important in vehicles that carry heavy loads, as it ensures consistent performance and safety.

Another important role of the leaf spring clamp kit is contributing to the overall shock absorption of the vehicle. The friction between the leaves, enhanced by the clamps, helps dampen the effects of road bumps and vibrations. However, it's important to note that excessive friction can lead to wear and tear, which is why proper maintenance of the clamps is crucial for long-term performance.

The installation of leaf spring pack clamps is a straightforward process but must be done correctly to ensure optimal performance. Here are the general steps involved:

Lift the Vehicle: Start by lifting the vehicle and securing it on jack stands.

Remove the Old Clamps: If replacing old clamps, remove them carefully by loosening the bolts or fasteners.

Position the New Clamps: Place the new leaf spring clamp kit around the spring pack, ensuring that they are aligned correctly.

Tighten the Bolts: Once in place, tighten the bolts to the recommended torque specifications. Ensure that the clamps are snug, but avoid overtightening as this can cause damage to the spring pack.

Lower the Vehicle: After installation, lower the vehicle and perform a test drive to check for any unusual noise or handling issues.

Regular maintenance is vital for ensuring that the leaf spring clamps continue to perform optimally. Here are some maintenance tips:

Inspection: Periodically check the clamps for signs of wear, rust, or damage.

Lubrication: Apply lubrication to the clamps to reduce friction and prevent rusting.

Replacement: If a clamp is damaged or shows signs of wear, replace it immediately to avoid suspension system failure.

Spring Pack Shifting: If the clamps become loose or damaged, the individual leaves in the spring pack can shift, leading to instability.

Excessive Wear or Rust: Over time, leaf spring clamps can suffer from wear or rust, especially in vehicles exposed to harsh weather or road conditions.

Regular Inspections: Ensure that the clamps are regularly inspected and replaced if necessary.

Lubrication: Lubricate the clamps to reduce friction and prevent rusting.

Proper Installation: Always ensure that the clamps are properly installed and tightened to the correct specifications.

In conclusion, leaf spring clamps are an essential part of the suspension system, playing a key role in maintaining the stability, performance, and safety of the vehicle. Whether you are looking for a leaf spring clamp kit for a heavy-duty truck or a leaf spring pack clamp for a lighter vehicle, proper installation and maintenance are crucial for optimal performance. Regularly inspecting and replacing the clamps when needed will ensure that your suspension system continues to function as designed, providing a smooth and safe ride.