Views: 0 Author: LUEN Groups Publish Time: 2025-03-20 Origin: Site

Leaf springs are crucial for vehicle suspension, especially in heavy-duty applications like trucks and SUVs.

Over time, leaf springs can wear down, leading to a bumpy ride, reduced load capacity, and potential safety hazards.

Upgrading your leaf springs can enhance load-carrying ability, improve ride comfort, and increase ground clearance.

Various types of leaf springs cater to specific needs, including heavy-duty options and those designed for off-roading or towing.

Regular maintenance, including inspection and lubrication, can extend the life of your leaf springs.

The suspension system is very important for any vehicle. It helps provide a smooth ride by absorbing bumps from the road. A big part of many suspension designs, especially in trucks and heavy vehicles, is the leaf spring. This strong and simple part plays a big part in how well your vehicle rides, carries loads, and handles turns. Knowing how leaf springs work and when they need care can help improve your vehicle's performance and how long it lasts.

Imagine driving on a bumpy road. Without a good suspension system, every bump you hit would make the ride uncomfortable. Leaf springs are very important in solving this issue. They act as a link between the axle and the chassis. They take in shocks and vibrations from the road. This allows the wheels to move up and down without affecting the vehicle's body too much. As a result, passengers have a smoother ride, and it helps keep the car safe from damage.

Leaf springs are truly the backbone of a comfortable and stable ride. This is especially true when carrying heavy loads. They matter a lot for vehicles that need to do tough jobs, like towing or moving cargo. In these cases, leaf springs give the strength and support needed to deal with the extra weight and pressure.

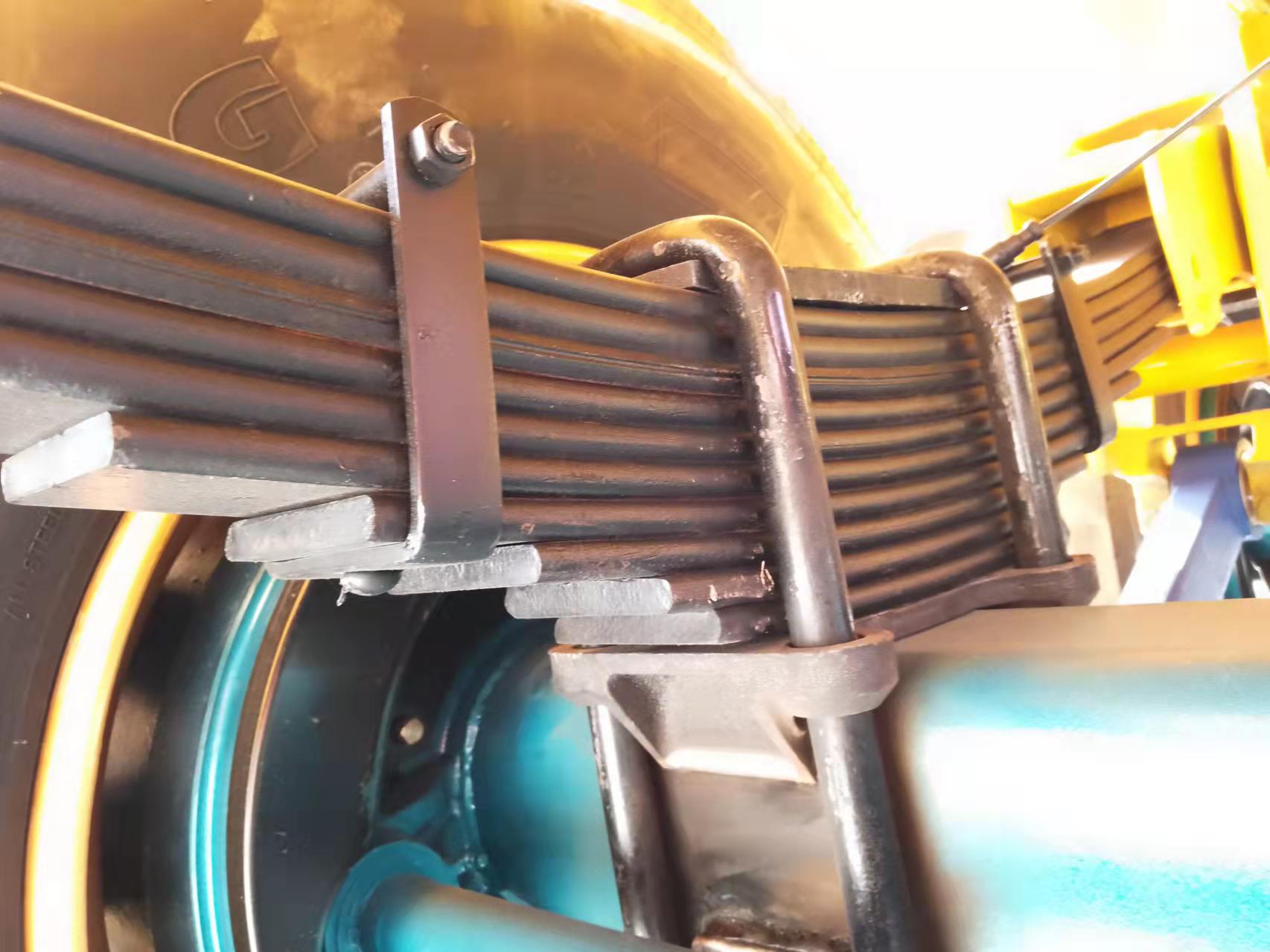

A leaf spring suspension system consists of several thin, curved steel plates. These plates are stacked together to form a shape that looks like a semi-ellipse. Each plate is called a 'leaf'. They are usually made of strong spring steel and arranged so that the longest leaf is at the top. This setup gives the spring its special strength and flexibility.

The leaf spring assembly connects to the vehicle's frame at both ends. It does this through openings at the end of the spring, known as 'eyes'. A bolt in the center of the leaf spring holds the spring pack and the bolts of the rear eye and bolts of the front eye to the axle assembly. This is usually the rear axle in most vehicles.

When the vehicle goes over bumps, the leaf springs bend and absorb shocks. This allows the axle to move up and down without tilting the vehicle much. This action helps keep the tires on the road, providing better grip and stability.

Upgrading your vehicle's leaf springs can give you many benefits. This is especially true if you often carry heavy loads or need better off-road performance. One main benefit is that you get a higher weight capacity. Heavy-duty leaf springs are made to support more weight without hurting your vehicle's stability or ride height.

Another advantage is that your ride quality gets better. Old leaf springs can make your ride feel rough and bumpy. But by switching to new, better leaf springs, you can enjoy a smoother journey, especially on tough roads.

New leaf springs can also help raise the height of your vehicle. This extra ground clearance is great for off-road lovers. It allows you to clear obstacles more easily and improves the angles for getting on and off ramps.

A good set of leaf springs can last a long time with proper care. But just like other parts of your vehicle, they can wear out with time. It's important to spot the signs of failing leaf springs. This way, you can fix problems before they become expensive repairs.

If you see your vehicle dropping, especially at the back, or if the ride feels rougher than normal, it might mean your leaf springs are worn out. Other signs to look for are squeaking or clunking sounds when driving, uneven wear on tires, and the vehicle tilting to one side.

One clear sign that leaf springs may be failing is when the rear of the vehicle sags due to excess weight. This happens when the leaf springs can't hold the vehicle's weight well enough, making the back lower than normal. Sagging can also cause uneven tire wear and affect how the vehicle drives.

Another sign to notice is if the ride feels rough or bumpy. If you feel every bump on the road, your leaf springs might not be working well to absorb shocks. This loss of comfort can harm other parts of the vehicle's suspension.

Worn leaf springs can also make noises like squeaking or clunking. You may hear these sounds when turning or going over bumps. These noises can come from different areas, like the shackle pin. The shackle pin connects the end of the leaf spring to the frame through the rear shackles. They can also come from the leaf spring pack itself if there is too much friction between the leaves.

Leaf springs are made to hold a certain weight. They can handle some changes in weight, but putting too much heavy load on them all the time can make them wear out faster. This happens because the extra weight puts a lot of pressure on the spring leaves, which can lead to tiredness and even breakage over time.

Also, overloading your vehicle can change the shape of the leaf springs. When this happens, the springs lose their ability to work well. This can seriously affect how high your vehicle sits, how it handles, and overall safety.

Always follow your vehicle's allowed weight limit, which includes both passengers and cargo. It's important to know what your leaf springs can handle. Spreading out the weight evenly can help reduce the stress and help them last longer.

The market has different types of leaf springs. Each type is made for certain vehicles and their needs. Choosing the right one is important. It helps keep your ride smooth, safe, and suited for its purpose.

Standard leaf springs are used in most regular cars. Heavy-duty Ford models are made for trucks and SUVs, including popular choices like Ford Motor models, including Ford vehicle models and General Motors Ford trucks. Knowing the differences helps you make a smart choice. Also, there are specialty leaf springs for specific uses like off-roading or towing. These offer better performance and last longer in tough situations.

Choosing the right leaf springs for your vehicle can drastically impact its performance and load-carrying abilities. If you primarily use your vehicle for everyday commuting and light hauling, standard leaf springs are generally sufficient. These springs offer a good balance of comfort and load capacity for regular use. However, if you frequently transport heavy loads or tow trailers, heavy-duty leaf springs are the way to go.

Heavy-duty leaf springs are engineered to handle significantly higher weight capacities compared to their standard counterparts. They are constructed from thicker gauge steel and often incorporate additional leaves, making them significantly more robust and resistant to sagging or deformation under pressure.

Feature | Standard Leaf Springs | Heavy-Duty Leaf Springs |

|---|---|---|

Load Capacity | Lower | Higher |

Durability | Moderate | High |

Stiffness | Softer | Stiffer |

Best Fits | Passenger cars, light trucks | Heavy-duty trucks, towing vehicles |

Specialty leaf springs go beyond regular types, and they meet specific needs, especially for off-roading and towing. For example, off-road leaf springs help improve a vehicle's movement and ground clearance. This is important for driving on tough terrains.

These specialty leaf springs gain their better off-road performance through smart design features. They may be longer for more suspension movement, have a tapered shape for a smoother ride on rough surfaces, and use strong materials like chrome vanadium steel for great strength and durability in vehicles like the Chevy Camaro or the compact Matrix.

On the other hand, specialty leaf springs for towing are made to reduce sagging and keep the vehicle at a level height, even with heavy trailers attached. These springs usually have more leaves or use thicker steel to boost their weight capacity, making towing safer and more stable.

Upgrading leaf springs is a job that skilled DIY fans can do, or you can hire a qualified mechanic for help. Regardless of whether you go the DIY way or opt for a professional, knowing the process well is key for a good upgrade.

This section will help you through the key steps for upgrading your vehicle's leaf springs. We will talk about gathering the tools and materials you need. We will also ensure your installation is safe and goes smoothly, leading to better performance and a more comfortable ride.

Before starting a leaf spring upgrade, it's important to gather the right tools and materials. The most essential item is the replacement leaf springs. Make sure you select the correct type that fits your vehicle's year, make, and model.

For tools, you will need a good set. This set should include a socket wrench, torque wrench, breaker bar, jack stands, a floor jack, and penetrating oil. These tools help you loosen and take off bolts, support the vehicle's weight, and break down the leaf spring assembly.

You should also have some materials ready to make the process easier. This way, you'll need new U-bolts to hold the leaf springs to the axle, thread locker to keep bolts tight despite vibrations, and safety glasses and gloves to protect yourself during the work.

With your tools and materials ready, it's time to take out the old leaf springs. Safety is very important, so make sure the vehicle is on flat ground, such as in front of your house, and the parking brake is set.

Start by loosening the lug nuts on the wheels where you will replace the leaf springs, making sure to secure chocks before the vehicle's front wheels to prevent rolling.

Next, use the floor jack to carefully lift the vehicle to an elevated position. Make sure it is firmly supported on jack stands under the frame to ensure you have full access for better safety and convenience.

Always avoid working under a vehicle that is only on a jack.

Once the vehicle is safely lifted, you can start taking off the old leaf springs. This means you need to disconnect the shock absorbers, the brake lines (if needed), and the U-bolts that hold the leaf springs to the axle. Keep in mind that leaf springs are under tension, so be careful when removing the center bolt to stay safe.

With the old leaf springs taken out, you can now get ready to install the new ones. Start by checking the mounting points for any rust or damage. Fix any issues before you move on. Using a rust-inhibiting coating can help stop future rust.

Carefully line up the new leaf spring assembly with the forward mounts and the mounting points, ensuring the front of the leaf spring is correctly positioned at the front of the vehicle, with the front bushing of the replacement spring, the base plate, and the bolt head directed appropriately, as neglecting these details can lead to difficult years down the line. Make sure the center bolt of the leaf spring fits into the hole in the axle, keeping in mind the end measurement requirements. Put the new U-bolts in place and tighten them loosely first. After that, you can tighten them to the manufacturer's required torque.

Next, reconnect the shock absorbers and brake lines if needed. Then, lower the vehicle with the floor jack. Once the vehicle is down, tighten the lug nuts to the correct specifications while inspecting it from several different angles. Now, the installation of the new leaf springs is finished, allowing for better performance and a smoother, more comfortable ride.

After installing new leaf springs, you should take some steps to keep them working well and lasting long. Good maintenance is very important. It helps to avoid early wear and prevents problems later on.

Checking, cleaning, and greasing your leaf springs often can make them last longer. This way, you’ll keep enjoying a smooth and comfortable ride. Also, learning how to adjust leaf springs for the best ride can improve your overall driving experience.

Like any part of your vehicle, leaf springs need regular care to last long and work well. One easy way to maintain them is by keeping them clean. Over time, dirt, grease, and road debris can build up on the leaf springs. This can trap moisture, which leads to rust and damage.

Cleaning the leaf springs with a wire brush and soapy water now and then can help stop rust from forming and keep them working smoothly. After cleaning, it's important to grease the leaf spring bushings and shackles with good quality grease.

Lubrication reduces friction between moving parts. This helps to lower wear and tear. These straightforward maintenance tips can greatly extend the life of your leaf springs. This can help you avoid expensive repairs and keep your ride comfortable and safe for many miles.

Leaf spring suspensions are usually made for certain vehicles. You can make them even better by fine-tuning. This means adjusting the leaf spring tension, which is best done by a qualified mechanic who has the right tools and skills.

To change the leaf spring tension, you add or remove shims. Shims are thin metal plates that go between the leaf spring and the axle. If you add shims, the springs get stiffer and the ride feels firmer. If you remove shims, it makes the ride softer by lowering the spring rate.

Keep in mind that changing the leaf spring tension can change the ride height and other parts of the suspension. This is why it is important to understand what will happen when you make these changes. It is always a good idea to talk to a mechanic to make sure everything is done safely and correctly.

Upgrading leaf springs is an important step to make your vehicle ride better and carry more weight. Still, sometimes you may need to improve other parts of the suspension for an even better ride and comfort.

If your ride quality is not good enough even after changing the leaf springs, you might want to upgrade other suspension parts. These can include shock absorbers or putting in a suspension lift kit. Shock absorbers work with leaf springs to reduce bumps and keep your ride smooth.

Choosing high-quality shock absorbers that fit your vehicle and driving style can cut down on body roll. It can also make your ride feel better, especially on bumpy roads. Plus, putting in a suspension lift kit can increase ground clearance and help with off-road driving, making it a great choice for those who love to drive off the beaten path.

Even with careful maintenance and good care, leaf spring problems can still happen. These issues can come from regular use, heavy loads, or tough driving conditions. Knowing how to spot and fix these issues quickly can stop further damage and keep your vehicle running well.

This part will go over some common leaf spring problems. It will guide you on how to diagnose and troubleshoot these issues effectively. We will also talk about when you should get professional help for leaf spring repairs. This will help make sure your vehicle's suspension system lasts longer and works well.

Diagnosing problems with leaf springs starts with a close look at the whole suspension system. Check for damage like cracks, breaks, or rust on the leaf springs, shackles, and U-bolts. Also, look for sagging mainly at the back of the vehicle, as this might mean the springs are worn out.

Pay attention to strange sounds like squeaking, clunking, or banging, especially when you go over bumps or make turns. These noises could mean there are worn bushings, loose parts, or metal touching metal in the leaf spring pack. If you think your leaf springs have a problem, it is important to fix it quickly.

Depending on how serious the problem is, you may need to replace worn bushings or shackles, or you might need larger repairs or full leaf spring replacements. Talking with a qualified mechanic can help you find the best way to deal with your specific situation.

Some issues with leaf springs can be fixed with basic DIY skills. However, some problems need the help of a qualified mechanic. If you are uncomfortable working on your vehicle’s suspension or don’t have the right tools and knowledge, it's best to get professional help. This is always the safest choice.

Problems like severe rust, broken leaf springs, or alignment issues require special tools and skills. These issues should be left to trained professionals. Trying to fix them without proper training could further damage your vehicle or even make it unsafe.

Good mechanics have the experience, tools, and resources to diagnose and fix leaf spring issues correctly and safely. They can also suggest the best solution, whether it is a simple repair or a full leaf spring replacement, ensuring you get the correct parts for your vehicle’s suspension system. This helps keep your vehicle’s suspension system in great shape.

Upgrading the leaf springs in your vehicle can really improve how it performs, how much it can carry, and how comfortable it rides. Before you decide to make this change, it's important to think about the costs involved.

The costs can vary based on the type of leaf springs you choose, the brand, and whether you get help from a professional or do it yourself. This section will look at the cost factors for leaf spring upgrades. It will give you helpful information to make smart choices that fit your budget and goals for your vehicle.

The cost to replace leaf springs can change based on the year, make, and model of your car. It also depends on what type of leaf springs you select. Standard leaf springs usually cost less than heavy-duty or special ones made for off-roading or towing. When you think about the price, remember to include both the parts and the labor.

Leaf spring sets can cost a few hundred dollars for standard types. High-end, heavy-duty sets can cost over a thousand dollars. Labor costs for a mechanic can also vary based on their rate and how difficult the job is.

It's a good idea to get price quotes from different mechanics. This way, you can compare and get the best deal. Though cost is important, it shouldn't be the only thing you consider. Picking good quality leaf springs and trustworthy mechanics can help your suspension system last longer and make your driving experience better in the future.

One important choice you will make when upgrading leaf springs is whether to hire a professional or do it yourself. Hiring a professional is convenient and gives you peace of mind, but it costs more. Doing it yourself can save money, but you need mechanical skill, the right tools, and time.

If you are sure about your mechanical skills and have the right tools, installing leaf springs yourself can be a great way to save hundreds of dollars. But if you feel unsure about any part of the job or don't have the right tools, it is better to let a professional handle it.

Keep in mind that if you install it wrong, it can cause wear and tear, create safety risks, and lead to expensive repairs. Think about how comfortable you are, what tools you have, and the risks before choosing between a professional installation and doing it yourself.

Upgrading your leaf springs is a great way to improve your vehicle's suspension system. This can give you a smoother ride and better performance. It's important to know why leaf springs matter and to notice when they need upgrading. By doing this, you help keep your vehicle safe and efficient. You can choose from standard, heavy-duty, or specialty leaf springs. Make sure they are installed and maintained correctly to get the most out of your upgrade. Remember to think about costs and get professional help if needed. This way, you can enjoy a more comfortable and safe driving experience with enhanced leaf springs!

Leaf springs are important parts of vehicle suspension. They support the vehicle and help it stay steady. They also absorb shocks and vibrations from the road. These springs are key to keeping tires in touch with the ground. This helps to create a smoother and safer ride.

Signs that your leaf springs might need an upgrade are a droopy back end, a bumpier ride than normal, squeaks or clunks, tires wearing unevenly, and the vehicle tilting to one side. These all show that there is wear and possible problems with performance.

Upgrading to heavy-duty leaf springs made for towing can boost your vehicle's towing capacity. These springs are built to support heavier loads. They help reduce sagging and offer better stability.

Yes, there are laws to think about when changing a vehicle's suspension. These rules can be different depending on where you are. So, it's very important to look into and follow local laws about what changes you can make to ride height and suspension parts.

The time it takes to upgrade a leaf spring can change based on how complex the work is and how skilled the mechanic is. Generally, it may take a few hours or up to a full day to finish